|

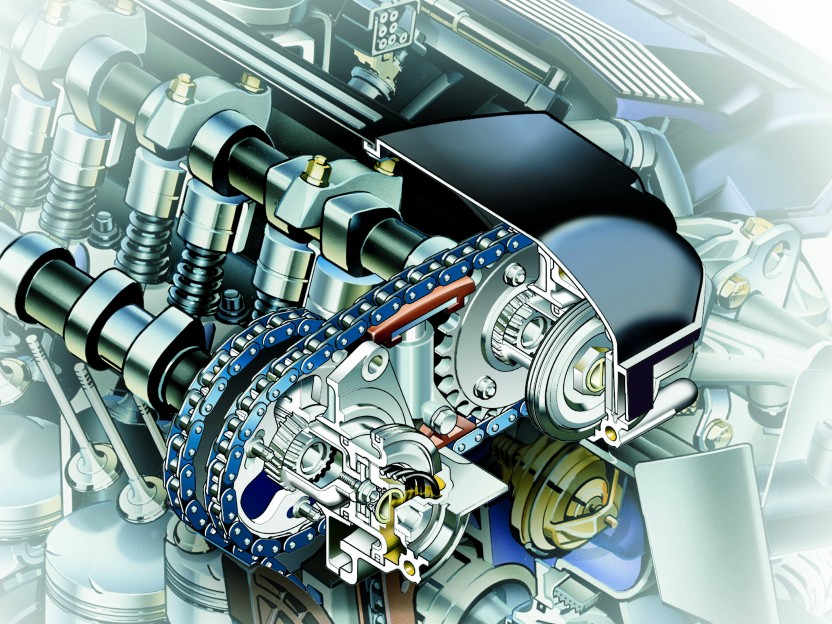

BMW Double VANOS

VANOS is a combined

hydraulic and mechanical camshaft control device managed by the

car's DME engine management system.

The VANOS system is based on an adjustment mechanism that can modify

the position of the intake camshaft versus the crankshaft.

Double-VANOS adds an adjustment of the intake and outlet camshafts.

VANOS operates on the intake camshaft in accordance with engine

speed and accelerator pedal position. At the lower end of the

engine-speed scale, the intake valves are opened later, which

improves idling quality and smoothness. At moderate engine speeds,

the intake valves open much earlier, which boosts torque and permits

exhaust gas re-circulation inside the combustion chambers, reducing

fuel consumption and exhaust emissions. Finally, at high engine

speeds, intake valve opening is once again delayed, so that full

power can be developed.

VANOS significantly enhances emission management, increases output

and torque, and offers better idling quality and fuel economy. The

latest version of VANOS is double-VANOS, used in the new M3.

Here's how it works:

In overhead cam engines, the cams are connected to the crankshaft by

either a belt or chain and gears. In BMW VANOS motors there is a

chain and some sprockets.

The crankshaft drives a sprocket on the exhaust cam, and the exhaust

cam sprocket is bolted to the exhaust cam. A second set of teeth

moves a second chain that goes across to the intake cam. The big

sprocket on the intake cam is not bolted to the cam, for it has a

big hole in the middle. Inside the hole is a helical set of teeth.

On the end of the cam is a gear that is also helical on the outside,

but it's too small to connect to the teeth on the inside of the big

sprocket. There is a little cup of metal with helical teeth to match

the cam on the inside and to match the sprocket on the outside. The

V (Variable) in VANOS is due to the helical nature of the teeth. The

cup gear is moved by a hydraulic mechanism that works on oil

pressure controlled by the DME.

At idle, the cam timing

is retarded. Just off idle, the DME energizes a solenoid which

allows oil pressure to move that cup gear to advance the cam 12.5

degrees at midrange, and then at about 5000 rpm, it allows it to

come back to the original position. The greater advance causes

better cylinder fill at mid rpm for better torque. The noise some

people hear is the result of tolerances that make the sprocket

wiggle a bit as the cup gear is moved in or out.

Double VANOS

Double-VANOS (double-variable camshaft control) significantly

improves torque since valve timing on both the intake and outlet

camshafts are adjusted to the power required from the engine as a

function of gas pedal position and engine speed.

On most BMW engines

that use a single VANOS, the timing of the intake cam is only

changed at two distinct rpm points, while on the double-VANOS

system, the timing of the intake and exhaust cams are continuously

variable throughout the majority of the rpm range.

With double-VANOS, the opening period of the intake valves are

extended by 12 degrees with an increase in valve lift by 0.9 mm.

Double-VANOS requires very high oil pressure in order to adjust the

camshafts very quickly and accurately, ensuring better torque at low

engine speeds and better power at high speeds. With the amount of

un-burnt residual gases being reduced, engine idle is improved.

Special engine management control maps for the warm-up phase help

the catalytic converter reach operating temperature sooner.

Double-VANOS improves low rpm power, flattens the torque curve, and

widens the powerband for a given set of camshafts. The double-VANOS

engine has a 450 rpm lower torque peak and a 200 rpm higher

horsepower peak than single-VANOS, and the torque curve is improved

between 1500 - 3800 rpm. At the same time, the torque does not fall

off as fast past the horsepower peak.

The advantage of double-VANOS is that the system controls the flow

of hot exhaust gases into the intake manifold individually for all

operating conditions. This is referred to as "internal" exhaust gas

re-circulation, allowing very fine dosage of the amount of exhaust

gas recycled.

While the engine is warming up, VANOS improves the fuel/air mixture

and helps to quickly warm up the catalytic converter to its normal

operating temperature. When the engine is idling, the system keeps

idle speeds smooth and consistent thanks to the reduction of exhaust

gas re-circulation to a minimum. Under part load, exhaust gas

re-circulation is increased to a much higher level, allowing the

engine to run on a wider opening angle of the throttle butterfly in

the interest of greater fuel economy. Under full load, the system

switches back to a low re-circulation volume providing the cylinders

with as much oxygen as possible.

Original Text:

http://www.bmwworld.com/technology/vanos.htm |

|

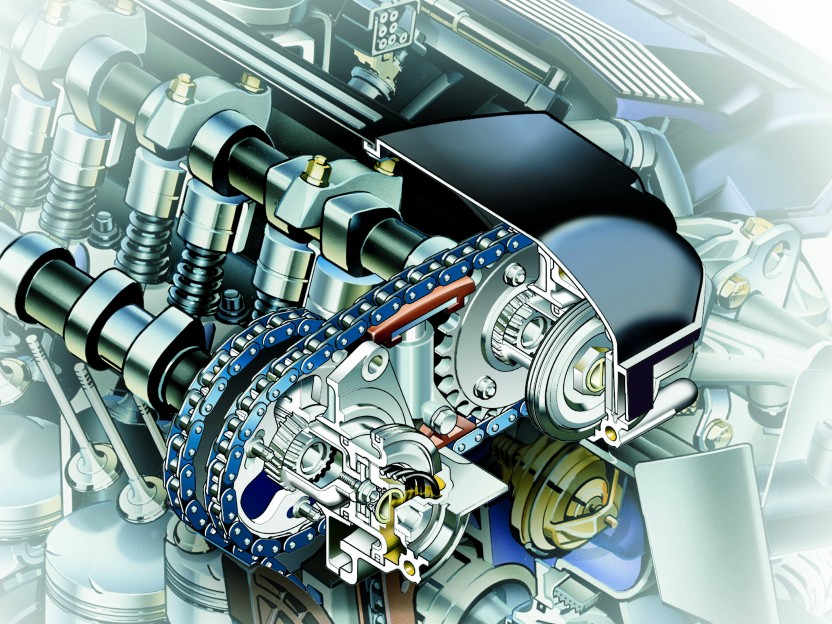

BMW M54 Engine

In an era of V-6

designs, why a straight-six?

The laws of physics; a straight-six power unit offers the optimum

physical configuration for a six-cylinder engine.

The near perfect inner balance of the straight-six means an absence

of free mass forces.

The straight-six does not require balance shafts and elaborate

engine mounts to overcome the inherent vibrations of other designs.

With valve drive systems becoming more complex, there are

engineering advantages in having only one cylinder head and only one

valve train.

The Design of the Straight-Six

More power, more fuel economy. Here's how:

The M54 has an aluminum crankcase with cast cylinder liners. The

engine size has been increased from the 2.8 liters of the M52 model

to 3.0 liters by increasing the cylinder stroke from 84.0 to 89.6

mm. With the increase in engine size, engine power has been

increased from 142 kW/193 hp to 170 kW/231 hp. The increase in the

opening period of the intake valves resulted in an increase of 3.5

kW/4.8 hp in engine output. The intake and exhaust manifolds have

been streamlined. This improvement contributed 16 kW/22 hp to the

increase in engine output. Other refinements result from reducing

piston friction and cutting back the engine's idle speed.

Electronic Throttle Butterfly

The throttle butterfly has now been replaced by a fully

electronic version.

The system recognizes the gear in which the car is driving and is

thus able to activate an individually programmed throttle butterfly

control line for each gear. Cruise control has been integrated

within the electronic throttle butterfly. Since there are no

conventional mechanical linkage bars, there is a reduction of gas

pedal forces. The phrase "step on the gas" takes on a whole new

meaning! The controls stored within the engine management system

have increased to over 600 different operating modes.

Engine Reliability

The M54 is the most reliable BMW engine ever built. Here's why:

The camshaft chain drive and the V-belt drive are maintenance-free

and designed for the life of the engine.

Valve clearances are kept consistent throughout the entire running

life of the engine by a self-adjusting hydraulic valve clearance

mechanism. There is no need to adjust valve clearances, ever.

There is no need to reset the clutch since it is self-adjusting.

The air filters and spark plugs only have to be replaced after

100,000 km or 62,000 miles.

The oil in the transmission and final drive is a lifetime filling

not requiring any replacement.

There is no need for any particular running-in service.

The BMW Service Interval Indicator informs the driver of the

remaining distance until the next oil change. You no longer have to

change the oil after a fixed, rigid mileage.

The engine is able to adjust automatically to all fuel grades

between 87 and 98 octane.

Anti-knock control automatically adjusts the engine's running

conditions to the respective fuel grade and quality.

Please note that the engine's maximum output is only achieved when

running on 98 octane premium fuel.

Specifications of 3.0L

Configuration - Straight-six

Market launch Year 2000

Max output kW/bhp 170 / 231 at 5900 rpm

Max torque Nm(lb-ft) 300 (221) from 3500-4750 rpm

Combustion process - Intake manifold injection / throttle control /

lambda = 1.0

Capacity, effective cc 2979.3

Compression ratio - 10.2

Bore / stroke mm 84 / 89.6

Crankcase material - Aluminum (AISi9Cu3) with cylinder liners

Height of cylinder block mm 211.0

Distance between cylinders mm 91

Topland mm 7

Main bearing diameter mm 60.0

Conrod bearing diameter mm 45.0

Conrod length mm 135, crack technology

Cylinder head material - Aluminum ((AISi6CU4)

Camshafts - 2 chain-driven camshafts running in 7 bearings and with

ultra-fine balance

Camshaft adjustment - Hydraulically infinitely variable phase

adjustment of the intake and outlet camshafts

Valve drive Cup tappets with hydraulic valve play compensation

Valve diameter intake/outlet mm 33.0 / 30.5

Valve shaft diameter intake/outlet 6.0 / 6.0

Valve angle intake/outlet 20 o 15' / 19 o 15'

Max valve lift, intake mm 9.7

Max valve lift, outlet mm 9.0

Opening period, intake o CS 240

Opening period, outlet o CS 244

Intake angle range o CS 86 - 126, infinitely variable

Outlet angle range o CS 80 - 105, infinitely variable

Intake manifold - Two-chamber resonance intake system with

additional turbulence unit

Engine weight according to BMW standard kg / lb 170 / 375

Engine management / fuel supply - Siemens MS43 / sequential

multipoint injection / fully electronic throttle butterfly

adjustment / additional turbulence system adjuster

Fuel grade RON 87 - 98 (rated output with 98 ROM fuel)

Certified emission standard - EU 4 / ULEV

Exhaust system - Shell manifold with three-way main catalysts close

to the engine; additional secondary air injection in some markets

Original Text:

http://www.bmwworld.com/engines/m54.htm |