The E46 M4 DCT Project

This is a long one.. Decided that my tired 5-speed that came with the car 20 years ago was not up to task with the freshly built engine. Investigating options, I decided to pioneer on this and install a GS7D36SG gearbox, basically a 7-speed, Dual Clutch Transmission (DCT) that came on the F8x series M2/M4 cars. This is the long-ratio gearbox with 2 overdrive gears. For controller, uppon recomendation, I decided to go with HTG GCU. This gearbox controller requires complete destruction of the OEM mechatronics unit inside the gearbox and changes are irreversable (unless you purchase a new mechatronic of course). Also wiring is needed within the gearbox.

The gearbox will bolt to the M54 block using the 4 main bolts. The starter ear also needed modification to make it accept an M54 starter as the 2nd starter hole does not lineup. At that time, there were not many options, now lots of adapters are available to make most of the custom work unneded. The 2 top bolt holes for the gearbox also need a bit of widening (with a file) to allow some rotation to clock it perfectly on the M54 block.

1. Flywheel: M4 DMF with M54 starter ring. This is a 6-bolt flywheel, which we fitted as we also modified the engine crankshaft from 8-bolt to 6-bolt pattern.

2. DCT gearbox

3. Control unit, HTG GCU

4. E92M3 flange on E46 front-half automatic driveshaft, rear-half stock.

5. DCT F-series Joystick gear lever, E46 M3 paddle shift,

6. E46 M3 SMG Cluster, with custom OLED CANBUS screen to show engaged gear and gearbox oil temp

7. OEM park lock module

8. E46 M3 gearbox mounts

9. Mod: Converted 6-bolt from 8-bolt M54 crankshaft

10. Fresh Gearbox oil pan + primary/secondary filters + 10liters of Motul DCTF

11. Crossmember: Custom made

12. Cooling: Setrab 25-row cooler with Davies, Craig 11″ cooling fan in front, digital temp control

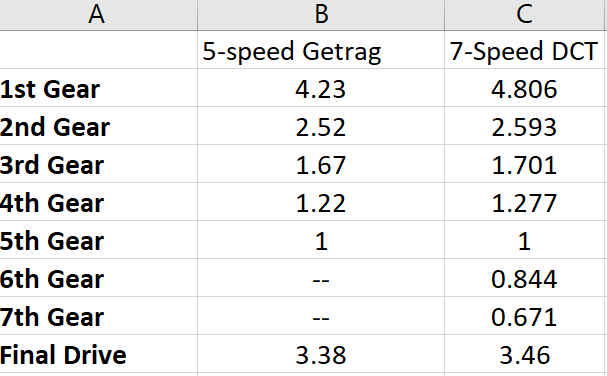

Ratios comparison:

Got a junk E46 auto gearbox for measurements and to “borrow” the starter ear from its bellhousing

Delivered:

Side by side:

Holes to be widened:

The E46 bellhousing:

M4 DCT with E46 style starter ear welded

Guibos compared..

Flywheels:

6-bolt Crank with M4 Flywheel. 2 holes already match, so it’s a matter of filling 6 hols and drilling/tapping 4 new holes

M4 flywheel positions the starter ring closer to the block, so we had to fabricate a spacer to move the starter back

Starter adaptor:

The GCU

I did a core-exchange for a modified mechatronics unit. If you hop on HTG’s website there are schematics and more details.

Installing the mechatronics inside the gearbox

All buttoned:

So, engine is in, along with the DCT. For the DCT cooling lines, we used the cooling lines from an automatic gearbox which apparently bolt on and pass through the various parts of the vehicle and end-up on the front. From there we will use the Setrab oil cooler. Regarding cross-member my mechanic decided to make his own. The part mentioned here that would fit is not available from BMW so I’d had to order it and wait about 2 weeks.

Driveshaft sorted. We are reusing the rear half part as it is to connect with the differential and have modified the front half part of an E46 automatic driveshaft to accept the huge flange out of an E92M3 driveshaft. The “benefit” is that the CSB is reused as it is, there is only 1 point of modification which makes balancing easier. The driveshaft is shorter obviously and only the thinner part of the tube has been removed – this is why the E46 auto was used, if we were to shorten the E46 manual driveshaft, the thicker part of the shaft would need to be cut.. Now some will argue about ability to hold power etc but I’m confident something else will probably fail way before the driveshaft or simply traction issues — rear components are still 320ci based.

Shifter / Joystick

Gearbox mount:

Paddleshifts

Exhaust adjusted a bit

Wiring

First roll:

Added a 3-bar map sensor to the GCU’s analogue inputs. Used to calculate engine torque as the standard MS43 torque reporting isn’t so accurate during boost

Cooling:

Park Lock Module. Used a modified drivelogic button to apply momentary 12v to the park lock solenoid to drop the park lock.

Hidden next to the driver’s seat, had to dig up the carpet to make room

And finally tuning the GCU… Like a million maps that the slightest adjustment does big changes.

With the above said, I also feel the need to share the setbacks and the various issues in doing this conversion. For sure it’s not easy and definitely it’s not for someone that would expect a plug-and-play package. There are 3 major components in this:

Mechanical Stuff

Custom fabrication needed to get a working driveshaft, gearbox mount, and a flywheel with adapter plate. At the monent, there are adapters available so someone could say it’s nearly plug and play. Filling the gearbox with oil and not running it (these were the instructions, not to run it) caused about 4L of oil short. You do not want to engage into anything before filling the DCT with absolutely correct amount of oil.

Electrical

The instructions are ok-ish but they do need improvement. You can order just the GCU and then find proper gauge/silicone oil resistant cables and plugs or purchase a wiring loom. Still the mechatronic unit needs to be destroyed (literally, with a chisel) to make room for the connections inside the solenoids. Now there are packages ready, from wiring loom, plugs, modified mechatronic with core return or complete gearbox.

The GCU has 2 Canbus lanes, which if used incorrectly, can cause havoc. Such as, ASC randomly kicking in, traction light on, gearbox light on etc. Plus the correct terminations need to be done as well. The fact that I used an M3 cluster on a non-M, we used the M3 canbus signal to send the gear indicator on the cluster, which conflicted with the operation of the ASC which apparently works different on an M3. Similar to IRQ/Memory conflicts. Whilst this is solvable, it significantly adds to any troubleshooting someone is doing. At the monent I have no gear indicator, so I have to resolve to ordering a separate one till a fix is available.

Tuning

I had no idea of the magnitute of this task. The fact that there are so many gearbox/engine/characteristics combinations makes it impossible for the tuner to provide a working base map. Even how used the dct clutches are, plays a role. The car could not move with the base map. Stalling, irregular shifting, etc. I am at good progress now, in creating a map, that will be definitely easier to adapt to an M54+DCT platform rather than start from scratch. The tuner is doing things remotely but its only minor adjustments. If someone expects a full remote tune from 0, better seek a different project.

And some clips: